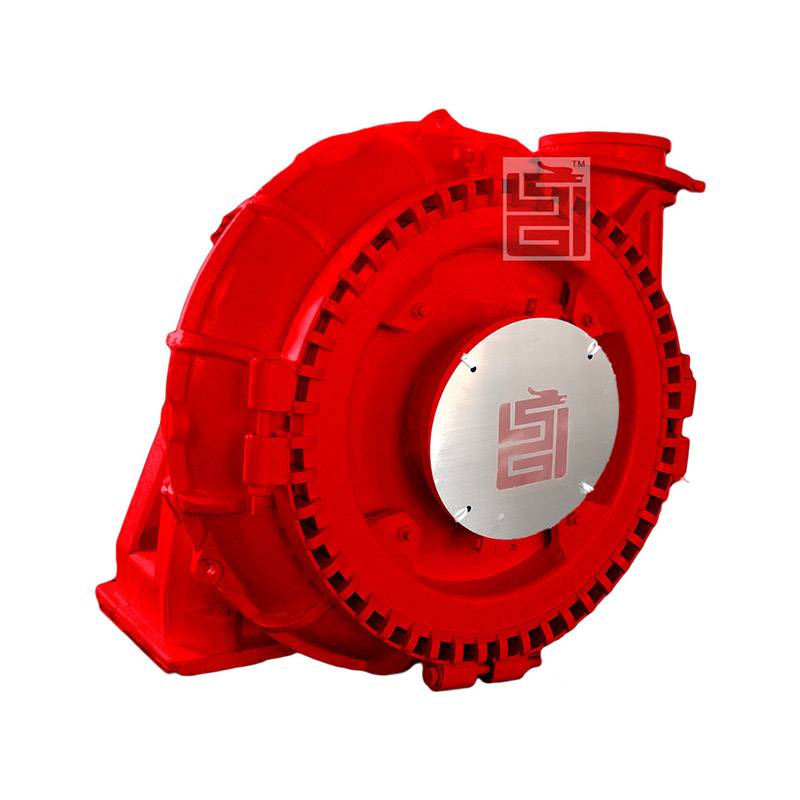

Centrifugal Slurry Pump Factory – Heavy duty cantilever sump pump – Panlong

Centrifugal Slurry Pump Factory – Heavy duty cantilever sump pump – Panlong Detail:

Materials:

High chrome alloy, Synthetic and natural rubber, Polyurethane, Corrosion resistant alloys

Material code reference:A05 and etc.

Elastomer rubber: Neoprene, Viton, EPDM, Rubber, Butyl, Nitrile, and specialty elastomers

Material code reference:S01/S02/S12/S21/S31/S42/S44

Polyurethane:U01,U05 and etc.

Description

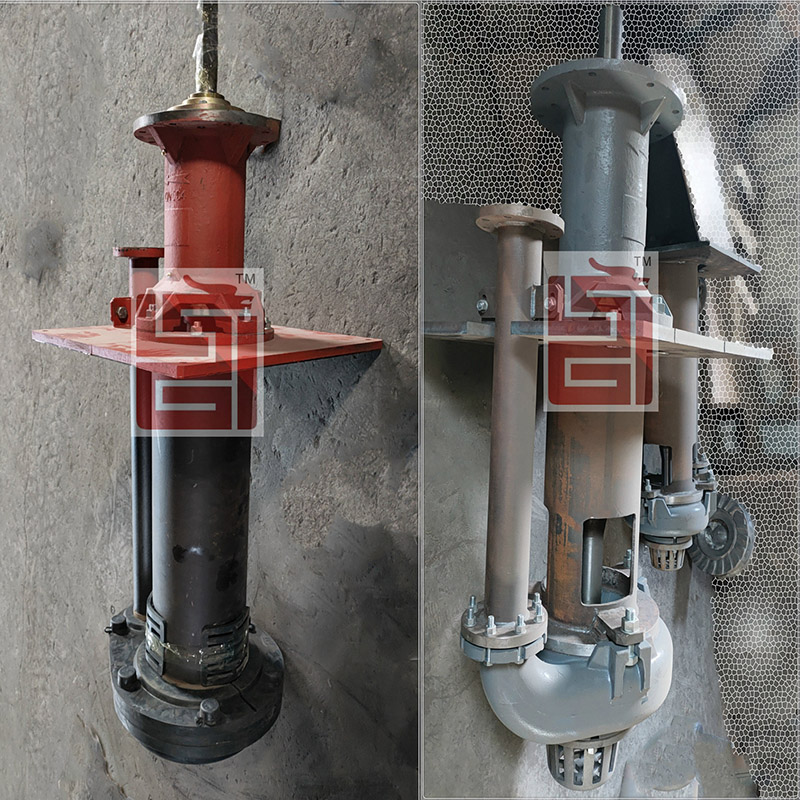

Panlong VP series heavy duty cantilever sump pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer.VP series vertical slurry pumps operate well for a variety of submerged suction pumping applications.

Fully elastomer lined or hard metal fitted. High capacity double suction design.

In addition, as a true cantilevered vertical slurry pump, the VP Series does not have submerged bearings or seals with a unique high capacity double suction design; thus, eliminating the primary failure mechanism for similarly fielded pump lines.Optional recessed impeller and suction agitator are available. The innovative product design and widely configurable range help our clients reduce costs.

VP pump – hard metal construction

VPR pump – rubber covered construction

Key Feature

1.Cantilevered shaft design– Eliminates submerged bearings, packing, lip seals, and mechanical seals that other vertical slurry pumps typically require.

2.Double suction semi-open impeller- fluid flow enters the top as well as the bottom. This design eliminates shaft seals and reduces thrust load on the bearings.

3.Recessed impeller option passes oversized material- Large particle impellers are also available and enable passing unusually large solids.

4.Fully elastomer lined or hard metal fitted to suit application and provide extended operating life- The metal pumps have a heavy walled abrasive resistant 27% chrome alloy casing. Rubber pumps have a molded rubber casing adhered to firm metal structures.

5.No submerged bearings or packing– The maintenance friendly bearing assembly has heavy duty roller bearings, robust housings, and a massive shaft.

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Centrifugal Slurry Pump Factory – Heavy duty cantilever sump pump – Panlong , The product will supply to all over the world, such as: Canberra, Austria, Jordan, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.