China Centrifugal Slurry Pump Supplier – Heavy duty cantilever sump pump – Panlong

China Centrifugal Slurry Pump Supplier – Heavy duty cantilever sump pump – Panlong Detail:

Materials:

High chrome alloy, Synthetic and natural rubber, Polyurethane, Corrosion resistant alloys

Material code reference:A05 and etc.

Elastomer rubber: Neoprene, Viton, EPDM, Rubber, Butyl, Nitrile, and specialty elastomers

Material code reference:S01/S02/S12/S21/S31/S42/S44

Polyurethane:U01,U05 and etc.

Description

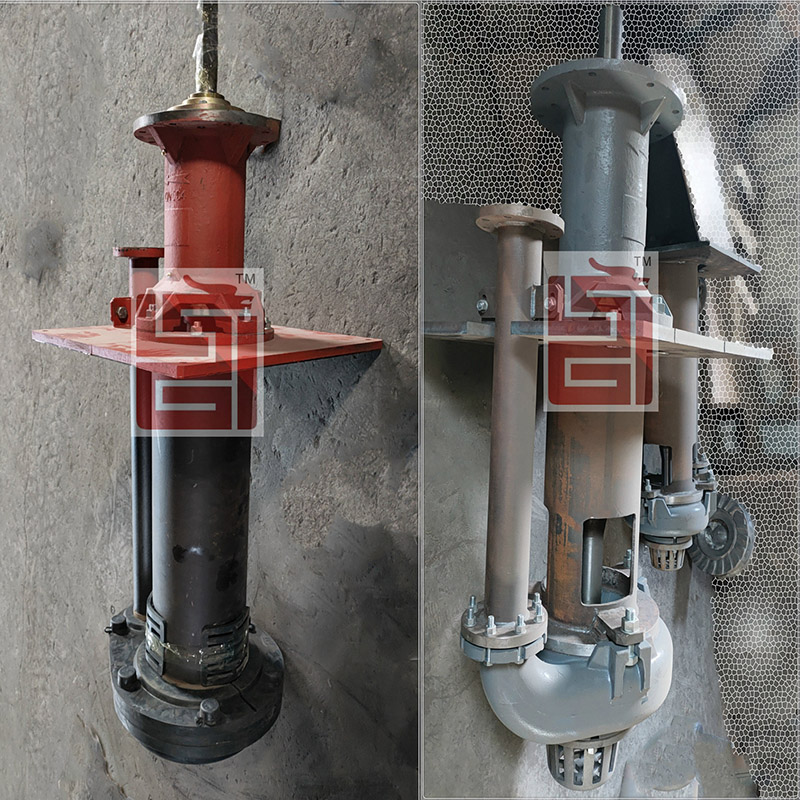

Panlong VP series heavy duty cantilever sump pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer.VP series vertical slurry pumps operate well for a variety of submerged suction pumping applications.

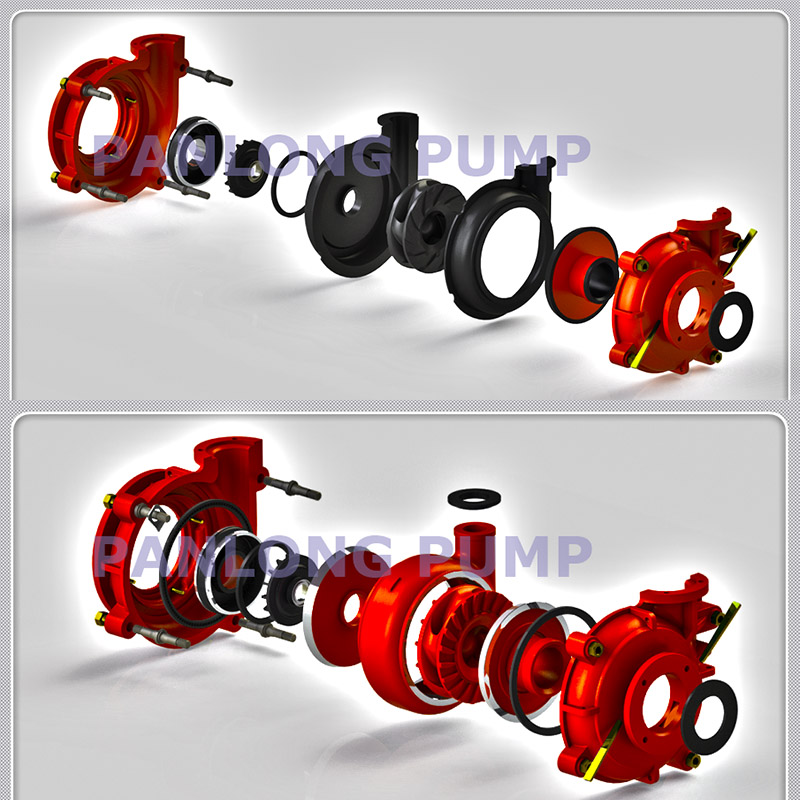

Fully elastomer lined or hard metal fitted. High capacity double suction design.

In addition, as a true cantilevered vertical slurry pump, the VP Series does not have submerged bearings or seals with a unique high capacity double suction design; thus, eliminating the primary failure mechanism for similarly fielded pump lines.Optional recessed impeller and suction agitator are available. The innovative product design and widely configurable range help our clients reduce costs.

VP pump – hard metal construction

VPR pump – rubber covered construction

Key Feature

1.Cantilevered shaft design– Eliminates submerged bearings, packing, lip seals, and mechanical seals that other vertical slurry pumps typically require.

2.Double suction semi-open impeller- fluid flow enters the top as well as the bottom. This design eliminates shaft seals and reduces thrust load on the bearings.

3.Recessed impeller option passes oversized material- Large particle impellers are also available and enable passing unusually large solids.

4.Fully elastomer lined or hard metal fitted to suit application and provide extended operating life- The metal pumps have a heavy walled abrasive resistant 27% chrome alloy casing. Rubber pumps have a molded rubber casing adhered to firm metal structures.

5.No submerged bearings or packing– The maintenance friendly bearing assembly has heavy duty roller bearings, robust housings, and a massive shaft.

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for China Centrifugal Slurry Pump Supplier – Heavy duty cantilever sump pump – Panlong , The product will supply to all over the world, such as: Mali, panama, Moldova, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.