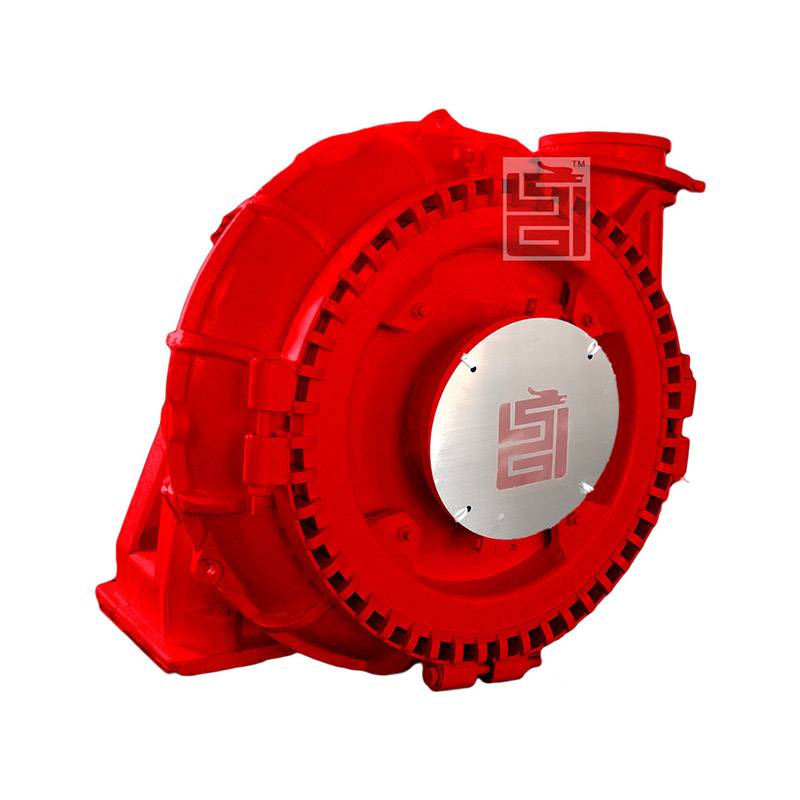

China Pump Of Slurry Factory – Light duty Slurry Pump – Panlong

China Pump Of Slurry Factory – Light duty Slurry Pump – Panlong Detail:

Materials:

High chrome iron, Synthetic and natural rubber, Polyurethane, Corrosion resistant alloys

High Chrome Alloy: high Chrome percentage’s available from 27-38% – Materials can be requested based on your working condition such as abrasiveness, impact, corrosiveness, PH levels, etc.

Material code reference:A05/A12/A33/A49/A61 and etc.

Elastomer rubber: Neoprene, Viton, EPDM, Rubber, Butyl, Nitrile, and specialty elastomers

Material code reference:S01/S02/S12/S21/S31/S42/S44

Description

The Panlong range of type L slurry pumps is designed for delivering higher volume and lower head slurries.They maintain the hardness and slurry handling flowrate of the P Series plus higher efficiency impellers at an attractive initial cost,along with a wider range of capacity and lower life-cycle costs. Type L slurry pumps were developed primarily for slurry handling duties in mining and chemical industries where slurry conditions are less rugged and the use of a lighter designed pump is economically justified. Alloy or thick elastomer internal liners provide superior erosion and corrosion resistance.Higher efficiency impellers make the L Series a valuable feature in any plant.

Each Panlong pump is carefully assembled and checked tolerance prior to hydraulic testing, allowing for immediate installation. Pumps can be fit up by customization to meet specific requirements from clients worldwide.

Key Feature

1.Large diameter, slow turning, high efficiency impellers (up to 90%+) result in maximum wear life and lower operating costs. Large, open internal passages reduce internal velocities maximizing wear life resulting in lower operating costs.

2.Standard bearing cartridge (grease lubricated SKF bearings)extending shaft lifecycle and reducing unexpected shutdowns and maintenance costs.

3.Modular design inner liner(wet ends) is ALL metal fit-up / ALL rubber fit-up (Natural Rubber,EPDM,Nitrile,Hypalon,Neoprene and etc.)

4.Multiple options of sealing type adapted to particular liquids and applications (gland packing, mechanical seal, expeller shaft seal)

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for China Pump Of Slurry Factory – Light duty Slurry Pump – Panlong , The product will supply to all over the world, such as: Provence, Maldives, Finland, We are looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.