OEM/ODM Slurry Pump Spare And Wear Parts Supplier – Pulp and Paper Process Pump APP – Panlong

OEM/ODM Slurry Pump Spare And Wear Parts Supplier – Pulp and Paper Process Pump APP – Panlong Detail:

Application

The Panlong process Pump of PA, PN, PW and PE ranges, has been designed for pumping all kind of liquids from clean waters to abrasive or corrosive liquids. Special capabilities to handle stocks of various kinds, sludges or slurries. Operation in industrial processes as below:

• Oil and Gas

• Hydrocarbon Processing

• Pulp and Paper

• Power Generation

• Water Transport and Distribution

• Food

• Basic Metals

• Fertilizers

• Customer Support Services

• Others

Features and Benefits

1. Versatile range of reliable and efficient particular impellers

Reduces life cycle costs, energy consumption, operation time and downtime

2. Innovative and reliable integrated degassing and self-priming units

For a variety of applications with difficult liquids

Designed to help the centrifugal pump start quickly when the liquid level is below the pump in self-priming applications

3. Robust, reliable and patented impeller mounting

Enables fast and simple dismantling and reassembly

Helps minimize maintenance costs

4. Externally adjustable patented side plate

Allows fast and simple impeller clearance setting, thereby minimizing life cycle costs and ensuring continued high efficiency

5. Patented balancing holes

Ensure efficient liquid circulation behind the impeller and in the seal chamber

Guarantee optimum shaft seal performance by reducing unexpected shutdowns and minimizing operation and maintenance costs

6. Proven Without water shaft seal

Effective dynamic, single and double mechanical seals and gland packing

Fast and simple installation

No measurement required

7. Heavy-duty shaft

• Reduces deflection at stuffing box to <0.05 mm / 0.002 in

• Helps extend shaft seal lifecycle and reduces unexpected shutdowns and maintenance costs

8. Reliable bearing unit

Reliable, simplified, heavy-duty bearing unit minimizes unexpected shutdowns and reduces maintenance costs

Includes oil and grease lubrication for all performance needs: grease lubrication for applications up to 120°C / 250°F; and oil lubrication for up to 180°C / 355°F

9. Jackscrews

Enable simple dismantling and minimizes maintenance costs

Standardization

Common components and modules in range types A, APP/T, EPP/T, NPP/T and WPP/T, with all options of gas separator GM, GS, R, self-priming LM and S, as well as CC designs are:

173 wet end sizes

24 sealing unit sizes with 7 common shaft seal sizes

7 common bearing units

Common sealing water equipment

Common couplings and coupling guards

Common baseplates

A Performance

Head up to 160 m

Temperature max. 180 °C

Capacity up to 2000 l/s

Operating frequencies 50 or 60 Hz

Pressure up to 1.6 MPa

(depending on material and size)

E Performance

Head up to 140 m

Temperature max. 210 °C

Capacity up to 1700 l/s

Operating frequencies 50 or 60 Hz

Pressure up to 2.5 MPa

N Performance

Head up to 90 m

Temperature max. 180 °C

Capacity up to 550 l/s

Operating frequencies 50 or 60 Hz

Pressure up to 1.6 MPa

(depending on material and size)

W Performance

Head up to 110 m

Temperature max. 180 °C

Capacity up to 2000 l/s

Operating frequencies 50 or 60 Hz

Pressure up to 1.6 MPa

(depending on material and size)

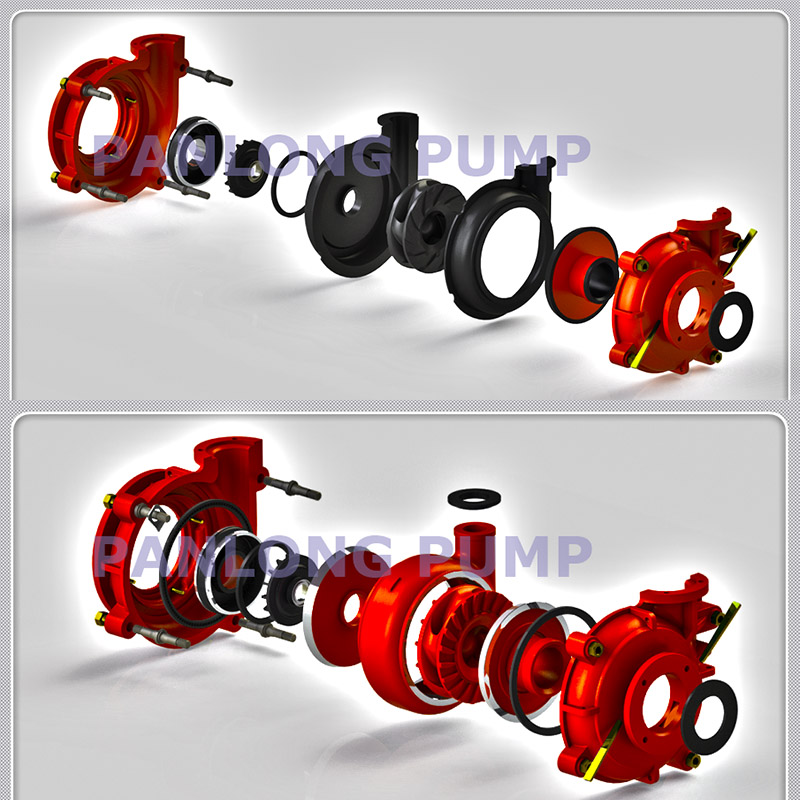

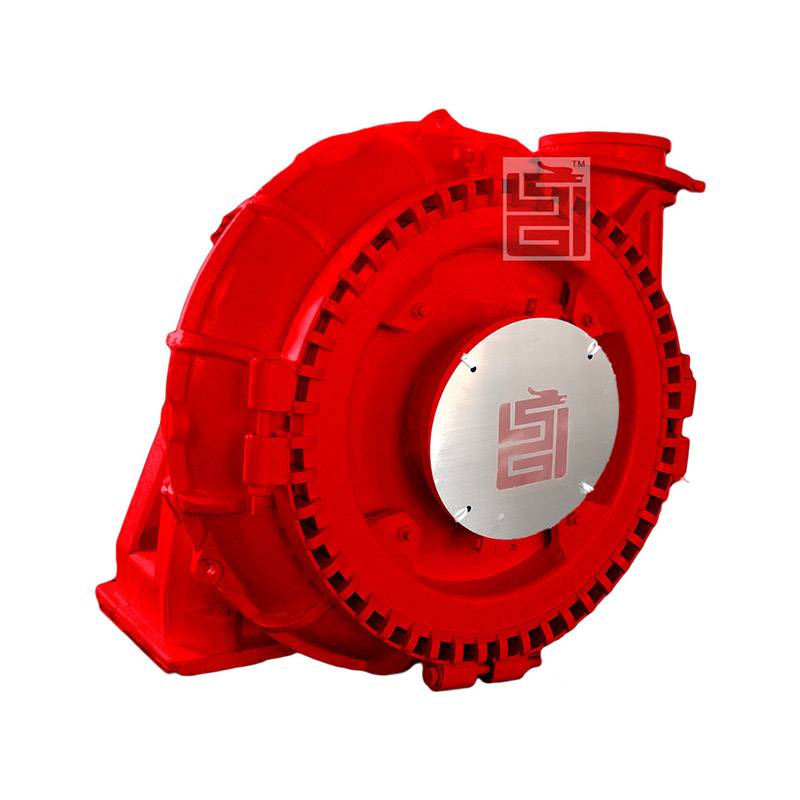

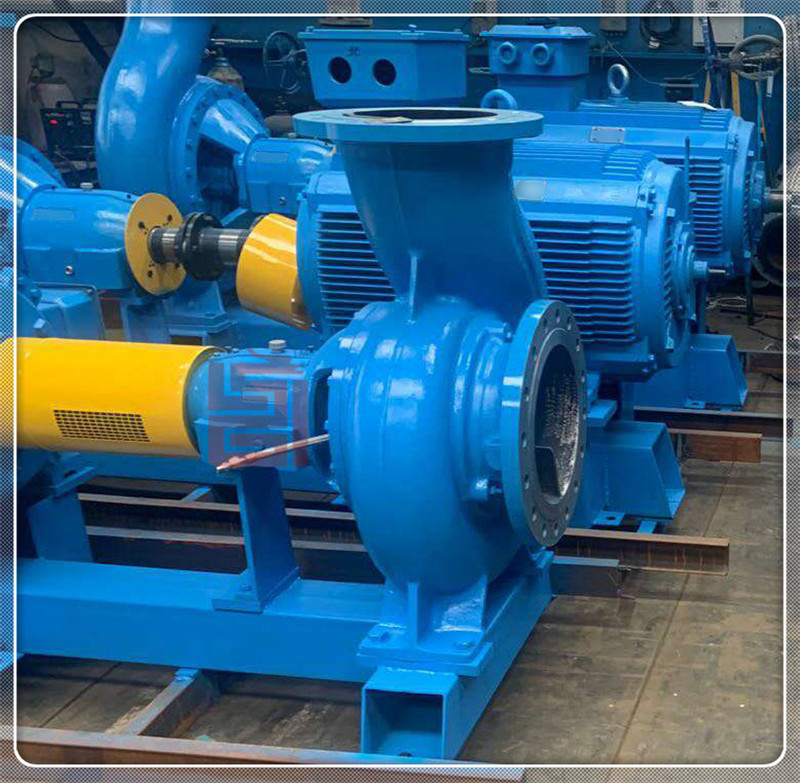

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for OEM/ODM Slurry Pump Spare And Wear Parts Supplier – Pulp and Paper Process Pump APP – Panlong , The product will supply to all over the world, such as: Russia, Afghanistan, Canberra, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!