OEM/ODM Slurry Pumps Manufacturer – Heavy duty slurry pump – Panlong

OEM/ODM Slurry Pumps Manufacturer – Heavy duty slurry pump – Panlong Detail:

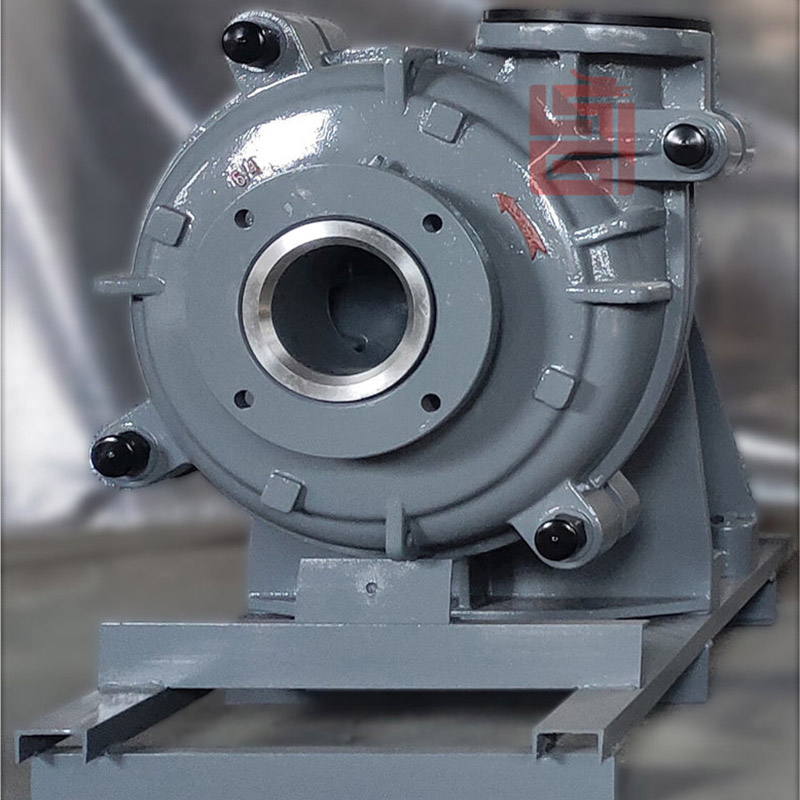

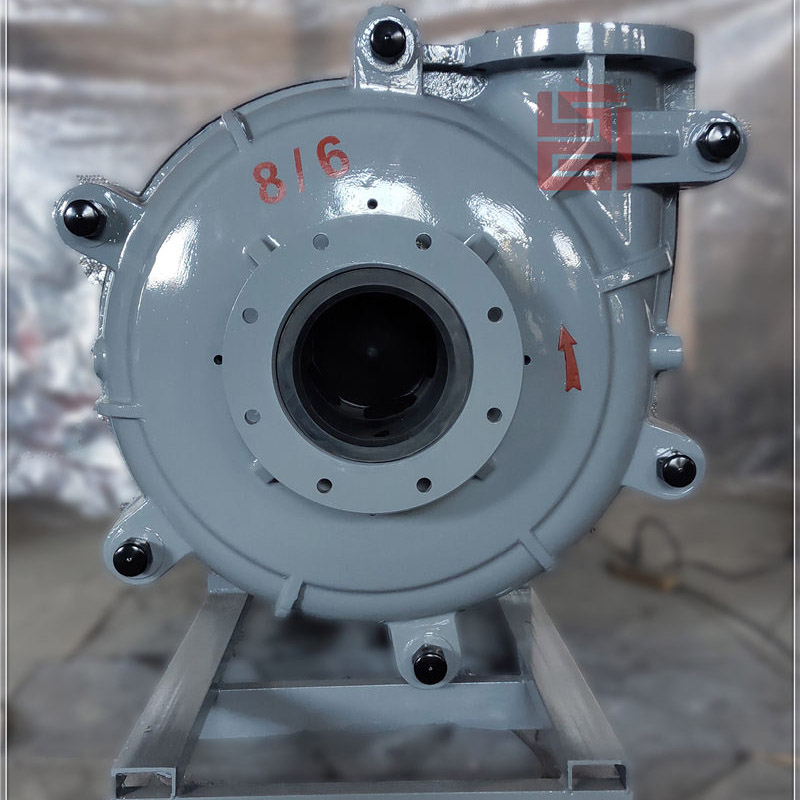

The Panlong range of P pumps designed as end-suction, split-casing, centrifugal slurry pumps is at the heart of a mine site for heavy duty abrasive pumping applications such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include mineral processing, coal prep, aggregate processing, fine primary mill grinding, chemical slurry service, tailings, industrial processing, cracking operations, ash handling, ball mill discharge and etc.

With large shaft diameters, heavy duty bearing assemblies and robust slurry pumping capacity, Panlong slurry pumps provide a cost-effective and ideal alternative capable of helping eliminate your existing pump vibrating, cavitating or leaking.We deeply know your pumping equipment is crucial to the task.

Panlong industrial pumps range in size from 1.5×1 to 20×18. Each pump is carefully assembled and checked tolerance prior to hydraulic testing, allowing for immediate installation. Pumps can be fit up by customization to meet specific requirements from clients worldwide.

Product Parameters

|

P Series Model |

Bearing Assembly |

Suction x Discharge (inches, [mm]) |

Nominal Impeller* Diameter (inches, [mm]) |

Solid Particle Passing, Φ* (inches, [mm]) |

Impeller* Materials |

Liner Materials |

| 1.5/1 | B | 1.5×1 [40x25] | 5.98 [152] | 0.55 [14] | Chrome lron(s) and Elastomer(s) Available.NOTE: Open face,large particle and specialized impellers available upon request. | Chrome lron(s) and Elastomer(s) Available |

| 2/1.5 | B | 2×1.5 [50x40] | 7.24 [184] | 0.75 [19] | ||

| 3/2 | C | 3×2 [75x50] | 8.43 [214] | 0.98 [25] | ||

| 4/3 | C,D | 4×3 [100x75] | 9.65 [245] | 1.42 [36) | ||

| 6/4 | D, E | 6x4 [150x100] | 14.37 [365] | 2.01 [51] | ||

| 8/6 | E, F | 8×6 [200x150) | 20.08 [510] | 2.48 [63] | ||

| 10/8 | F,S | 10×8 [250x200] | 27.01 [686] | 2.99 [76] | ||

| 12/10 | S,G | 12×10 [300x250] | 30.00 [762] | 3.39 [86] | ||

| 14/12 | S,G,T | 14×12 [350x300] | 37.99 [965] | 3.54 [90] | ||

| 16/14 | G, T | 16×14 [400x350] | 42.01 [1067] | 5.31 [135] | ||

| 20/18 | T | 20×18 [500x450] | 53.94 [1370] | 5.12 [130] | Chrome Iron | |

| *Standard impeller (typically five vane, chrome iron, closed face) | ||||||

CC,DD,EE,FF frame and bearing assembly are available for your options

Key Feature:

1.Variety of reliable and efficient impeller options (open, closed, non-clogging, with 2, 3, 4 and 5 vanes), fast and easy dismantling-reassembly during shutdown.

2.Standard bearing cartridge (grease lubricated SKF bearings)extending shaft lifecycle and reducing unexpected shutdowns and maintenance costs.

3.Modular design inner liner(wet ends) is ALL metal fit-up / ALL rubber fit-up (Natural Rubber,EPDM,Nitrile,Hypalon,Neoprene and etc.)

4.Multiple options of sealing type adapted to particular liquids and applications (gland packing, mechanical seal, expeller shaft seal)

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for OEM/ODM Slurry Pumps Manufacturer – Heavy duty slurry pump – Panlong , The product will supply to all over the world, such as: Curacao, Miami, Russia, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.