Sludge Pump Vs Slurry Pump Supplier – Medium duty slurry pump – Panlong

Sludge Pump Vs Slurry Pump Supplier – Medium duty slurry pump – Panlong Detail:

Materials:

High Chrome Alloy: high Chrome percentage’s available from 27-38% – Materials can be requested based on your working condition such as abrasiveness, impact, corrosiveness, PH levels, etc.

Material code reference:A05/A12/A33/A49/A61 and etc.

Elastomer rubber: Neoprene, Viton, Urethane, EPDM, Rubber, Butyl, Nitrile, and specialty elastomers

Material code reference:S01/S02/S12/S21/S31/S42/S44

Polyurethane:U01,U05 and etc.

Description

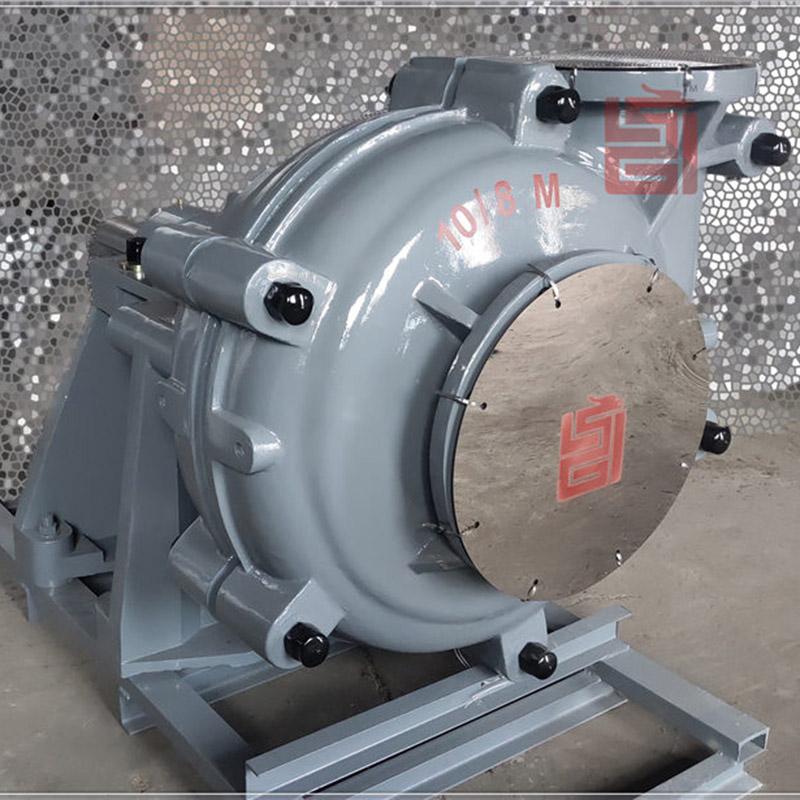

The range of Panlong M(R) lined pump is a kind of middle duty slurry pump, is applied to deliver the fine particle size and middle density sludge. M Pumps are cantilevered, horizontal and centrifugal slurry pumps with double casing. They are very close to series P structure but designed for pumping medium concentration slurries, widely used in coal washer processing, handling with the fine ore and tailings in mineral mines, pumping combined bottom and fly ash in a thermal power station etc.

Each Panlong pump is carefully assembled and checked tolerance prior to hydraulic testing, allowing for immediate installation. Pumps can be fit up by customization to meet specific requirements from clients worldwide.

Conveying slurry is at the heart of a mine site, so we deeply know your pumping equipment is crucial to the task. Panlong pump could eliminate your existing pump vibrating, cavitating or leaking.

Key Feature

1.Standard reliable and efficient impeller options,fast and easy dismantling-reassembly during shutdown.

2.Standard bearing cartridge (grease lubricated SKF bearings)extending shaft lifecycle and reducing unexpected shutdowns and maintenance costs by retaining in a clean environment without disassembling the pump for reliable operation and extended bearing life

3.Modular design inner liner(wet ends) is ALL metal fit-up / ALL rubber fit-up (Natural Rubber,EPDM,Nitrile,Hypalon,Neoprene and etc.)

4.Multiple options of sealing type adapted to particular liquids and applications (gland packing, mechanical seal, expeller shaft seal)

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Sludge Pump Vs Slurry Pump Supplier – Medium duty slurry pump – Panlong , The product will supply to all over the world, such as: Belgium, Brasilia, Iran, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!