Slurry Pumps Factory – Heavy duty slurry pump – Panlong

Slurry Pumps Factory – Heavy duty slurry pump – Panlong Detail:

The Panlong range of P pumps designed as end-suction, split-casing, centrifugal slurry pumps is at the heart of a mine site for heavy duty abrasive pumping applications such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include mineral processing, coal prep, aggregate processing, fine primary mill grinding, chemical slurry service, tailings, industrial processing, cracking operations, ash handling, ball mill discharge and etc.

With large shaft diameters, heavy duty bearing assemblies and robust slurry pumping capacity, Panlong slurry pumps provide a cost-effective and ideal alternative capable of helping eliminate your existing pump vibrating, cavitating or leaking.We deeply know your pumping equipment is crucial to the task.

Panlong industrial pumps range in size from 1.5×1 to 20×18. Each pump is carefully assembled and checked tolerance prior to hydraulic testing, allowing for immediate installation. Pumps can be fit up by customization to meet specific requirements from clients worldwide.

Product Parameters

|

P Series Model |

Bearing Assembly |

Suction x Discharge (inches, [mm]) |

Nominal Impeller* Diameter (inches, [mm]) |

Solid Particle Passing, Φ* (inches, [mm]) |

Impeller* Materials |

Liner Materials |

| 1.5/1 | B | 1.5×1 [40x25] | 5.98 [152] | 0.55 [14] | Chrome lron(s) and Elastomer(s) Available.NOTE: Open face,large particle and specialized impellers available upon request. | Chrome lron(s) and Elastomer(s) Available |

| 2/1.5 | B | 2×1.5 [50x40] | 7.24 [184] | 0.75 [19] | ||

| 3/2 | C | 3×2 [75x50] | 8.43 [214] | 0.98 [25] | ||

| 4/3 | C,D | 4×3 [100x75] | 9.65 [245] | 1.42 [36) | ||

| 6/4 | D, E | 6x4 [150x100] | 14.37 [365] | 2.01 [51] | ||

| 8/6 | E, F | 8×6 [200x150) | 20.08 [510] | 2.48 [63] | ||

| 10/8 | F,S | 10×8 [250x200] | 27.01 [686] | 2.99 [76] | ||

| 12/10 | S,G | 12×10 [300x250] | 30.00 [762] | 3.39 [86] | ||

| 14/12 | S,G,T | 14×12 [350x300] | 37.99 [965] | 3.54 [90] | ||

| 16/14 | G, T | 16×14 [400x350] | 42.01 [1067] | 5.31 [135] | ||

| 20/18 | T | 20×18 [500x450] | 53.94 [1370] | 5.12 [130] | Chrome Iron | |

| *Standard impeller (typically five vane, chrome iron, closed face) | ||||||

CC,DD,EE,FF frame and bearing assembly are available for your options

Key Feature:

1.Variety of reliable and efficient impeller options (open, closed, non-clogging, with 2, 3, 4 and 5 vanes), fast and easy dismantling-reassembly during shutdown.

2.Standard bearing cartridge (grease lubricated SKF bearings)extending shaft lifecycle and reducing unexpected shutdowns and maintenance costs.

3.Modular design inner liner(wet ends) is ALL metal fit-up / ALL rubber fit-up (Natural Rubber,EPDM,Nitrile,Hypalon,Neoprene and etc.)

4.Multiple options of sealing type adapted to particular liquids and applications (gland packing, mechanical seal, expeller shaft seal)

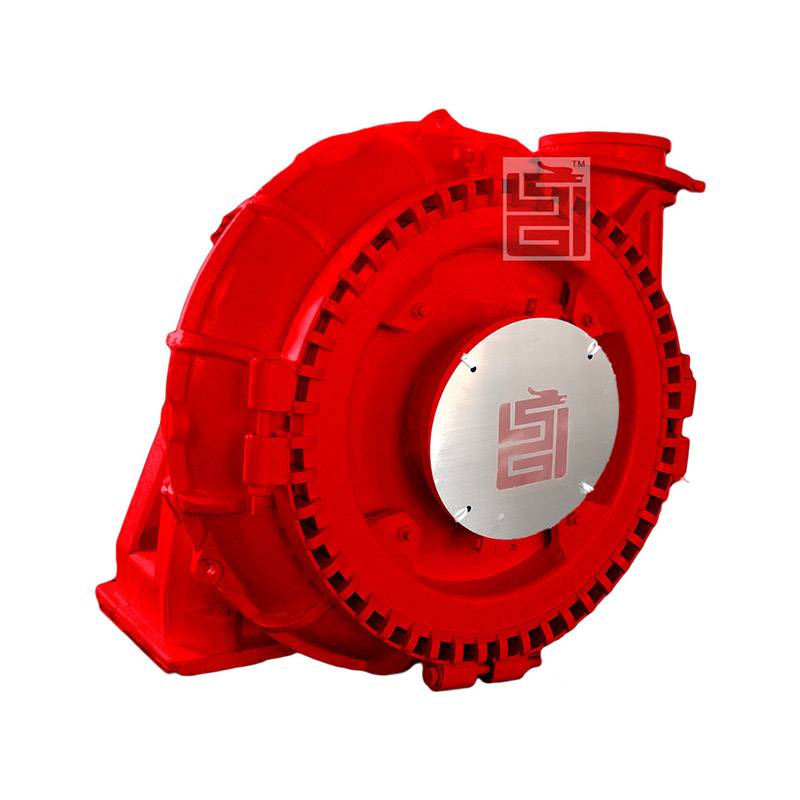

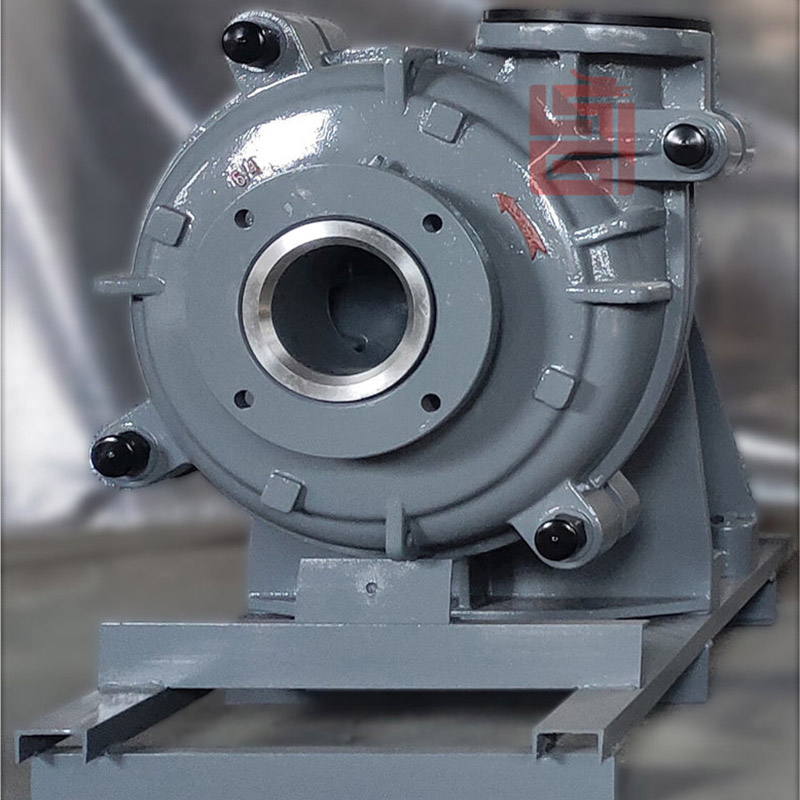

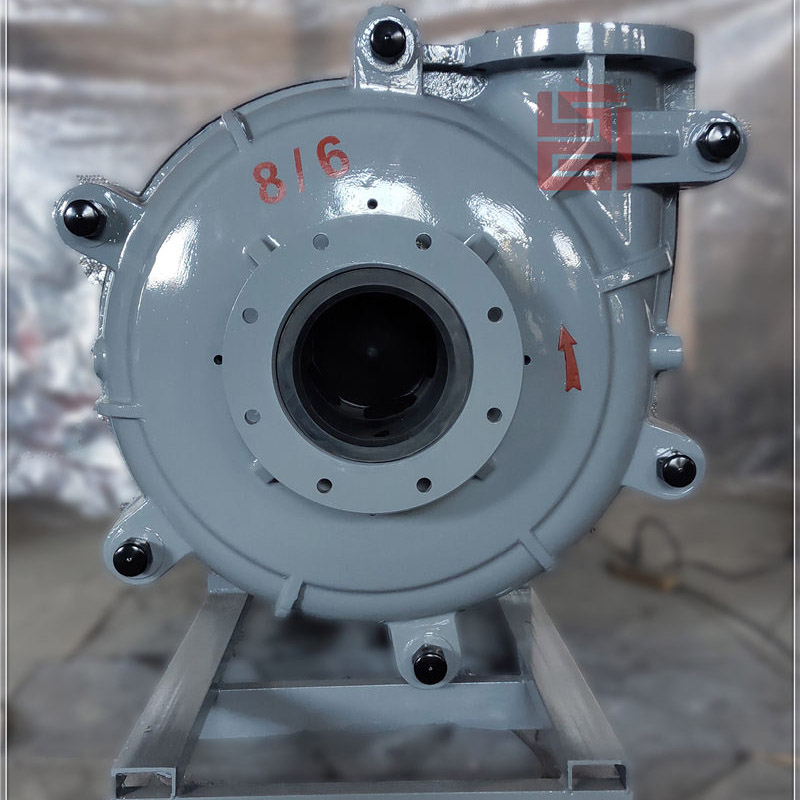

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Slurry Pumps Factory – Heavy duty slurry pump – Panlong , The product will supply to all over the world, such as: USA, Sudan, Malta, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share the top trading practical experience with all our merchants.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.